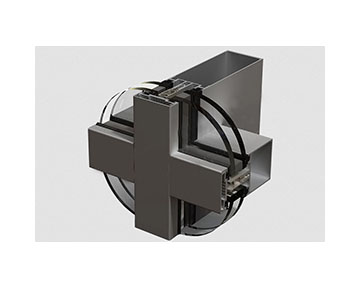

KMD – F50

- Free consultation and measurement

- Own production

- Only quality raw materials

- Focus on results, not benefits

- Extensive experience in performing complex objects

- A team of professionals able to solve any task according to the planned budget

- Full support and assistance 24/7/365

- We believe that "Quality can and should be available to everyone"

Product description:

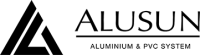

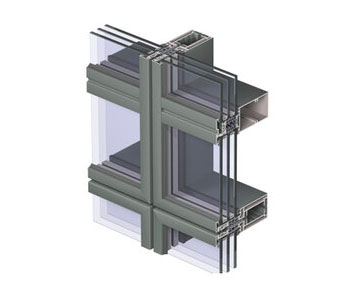

A series of aluminum profiles KMD.F50 is designed for the manufacture of translucent enveloping structures of buildings and structures. It is a widely used post-transom façade glazing system with a visible profile width of 50 mm.

The connection of the bearing profiles (posts and girders) is carried out, as a rule, with an overlap – by overlapping the girder on the post. It is also possible to join the post and the transom end-to-end.

The necessary supporting elements of the structure are selected depending on the design features of the designed object and the magnitude of the loads acting on the enclosing structure. Under the action of significant loads, special reinforcing profiles are used, which are inserted into the hollow chambers of the post and transom.

To compensate for changes in the dimensions of the profiles caused by temperature fluctuations, a gap (5-10 mm) is provided between the bearing posts, which is filled with a sealant during installation.

The design of the KMD.F50 system allows you to install the ledgers to the posts at an angle in the range of 7.5-45 ° using special adapters, nuts and clamping elements. This makes it possible to perform radius facade surfaces within a given curvature.

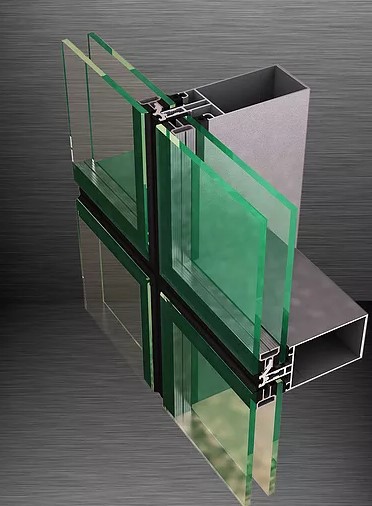

Filling of openings in aluminum structures is carried out with double-glazed windows or decorative heat-insulating panels. For sealing, gaskets based on ethylene propylene rubbers (EPDM) are used. To ensure standardized thermophysical parameters, a set of thermal inserts made of solid impact-resistant polyvinyl chloride (PVC) with high heat-insulating parameters is used in the structure.

The glazing is installed outside the building. The filling is fixed with clamping strips, which are attached to the supporting elements with self-tapping screws with a pitch of no more than 250 mm. The clamping strips, in turn, are closed with decorative covers.